Visually inspect the connecting rod and the cap for fretting damage on the mating surfaces.

The rod and the cap must be replaced as an assembly if any fretting damage is visible on either piece.

Visually inspect the ring dowels for cracks or damaged areas. Replace if necessary. Refer to Connecting Rod

Ring Dowel – Removal later in this section.

Inspect the rods and the caps for damage.

Replace the rod if the I-beam is nicked or damaged.

Visually inspect the rod pin bore bushing for damage or misalignment of the oil passage and the bushing.

Visually inspect the capscrew threads for damage.

Visually inspect under the capscrew heads for cracks.

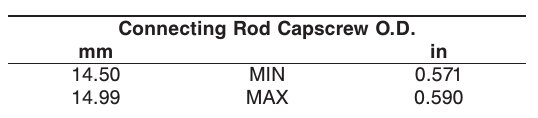

Measure the capscrew outside diameters.

Caution: The rod cap alpha-numeric characters must match the alpha-numeric characters on the connecting

rod and must be installed with the characters aligned to prevent damage to the connecting rods and crankshaft.

Use clean 15W-40 oil to lubricate the connecting rod capscrews.

Assemble the rod, the cap, and the capscrews.

Caution: Use a vise with brass jaws to hold the rod.

Notches, scratches, or dents in the I-beam will cause rod failure.

Tighten the capscrews in alternate sequence to the following torque values:

1. Tighten to 100 N•m [75 ft-lb].

2. Tighten to 264 N•m [195 ft-lb].

Measure the connecting rod bearing bore inside diameter.

If any of the measurements are not within the specifications, the rod must be repaired or replaced.

Measure the piston pin bushing inside diameter.

If the bushing does not meet the specifications, the rod must be replaced.

Caution: The connecting rod must be assembled with the capscrews tightened to specifications before stamp-

ing identification numbers or alpha characters on the rod.

If a new connecting rod is installed, always check the rod and cap assemblies identification to make sure it does

not match any of the other rod and cap assemblies in that engine. If it does, the rod and cap must be stamped so

they can be differentiated from the other rod and cap assemblies.

Refer to the Alternate Repair Manual, Bulletin No. 3379035, for procedures to magnetically check for cracks

in the connecting rods and capscrews.