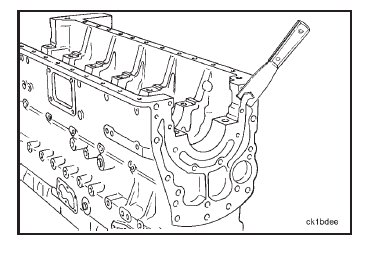

Caution: Do not damage the machined gasket surfaces or the camshaft bushings if the bushings have not been

removed.

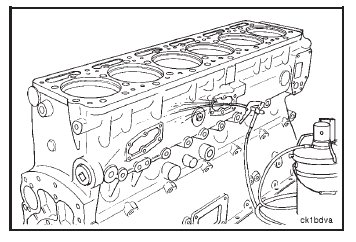

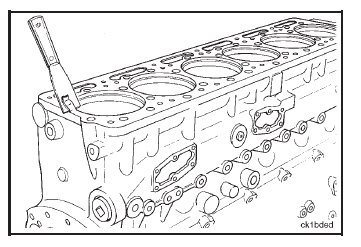

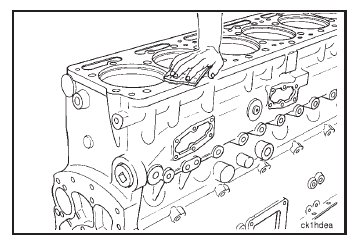

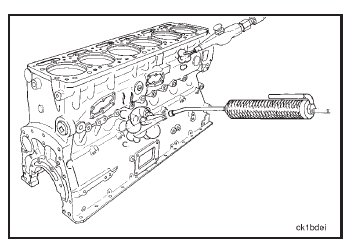

Use a gasket scraper, wire brush, or a fibrous abrasive pad such as Scotch-BriteT No. 7447, Part No. 3823258,

or its equivalent to clean heavy deposits off the cylinder block.

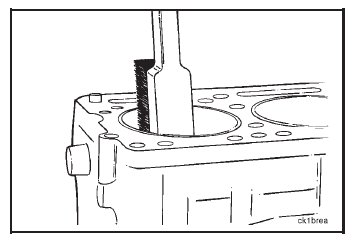

Clean the following cylinder block areas:

Cylinder liner counterbore ledge and press fit area.

Cylinder liner packing ring bore.

Cylinder head deck surface.

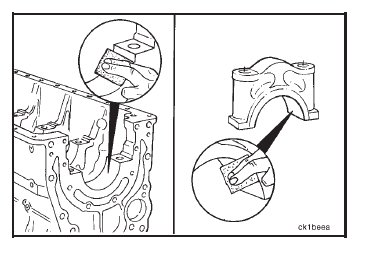

Main bearing saddles and caps.

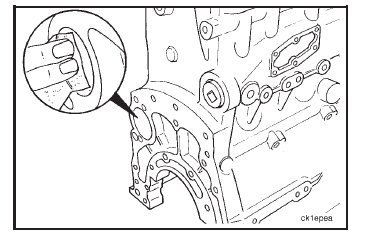

Camshaft bore cup plug area.

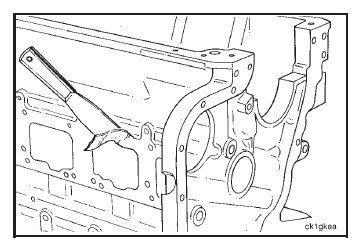

All gasket surfaces.

All component mounting surfaces.

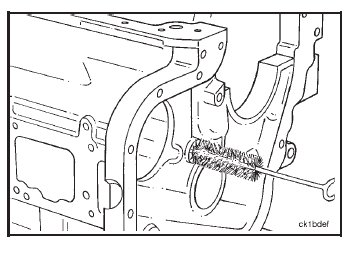

Clean all oil passages. Use a bottle brush with a long handle.

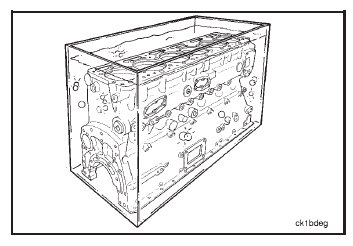

Warning: Use a face shield, rubber gloves, an apron, and boots and obey the warning label on the cleaning

solution used to prevent personal injury.

Caution: Use a cleaning solution that will not damage the camshaft bushings if the bushings have not been

removed.

Remove the block from the engine stand. Put the block in a cleaning tank.

Follow the instructions of the manufacturer of the cleaning tank and the manufacturer of the cleaning solution.

NOTE: Cummins Engine Company, Inc., does not recommend any specific cleaning solution.

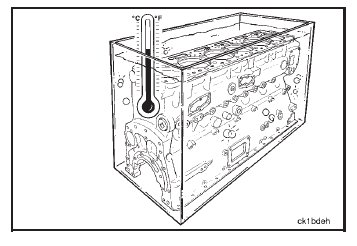

The best results can be obtained by using a cleaning solution that can be heated to 80° C to 95° C [180 ° F to

200° F].

Use a cleaning tank that will mix and filter the cleaning solution to get the best results.

Warning: Use a face shield, rubber gloves, an apron, and boots and obey the warning label on the cleaning

solution used to prevent personal injury.

Remove the block from the cleaning tank.

Clean all the oil passages using a steam cleaner.

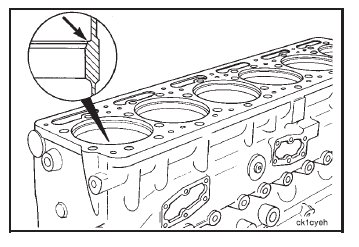

Caution: Make sure all the water is removed from the capscrew holes and the oil passages to prevent rust formation in the cylinder block.

Use compressed air to dry the block.

Warning: Naptha and methyl ethyl ketone (MEK) are flammable materials and must be used with care. Do not

use starting fluid as a cleaning agent. It can cause personal injury if ignited.

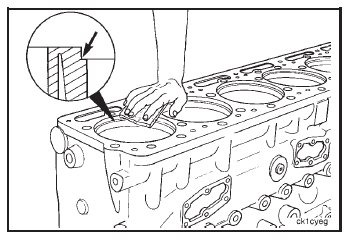

Clean the cylinder block counterbores with a suitable hydrocarbon solvent such as naptha, methyl ethyl ketone

(MEK), or trichlorethane 1, 1, 1 (methyl chloroform).

NOTE: If the cylinder block is not going to be used immediately, apply a coating of preservative oil to prevent rust.

Cover the block to prevent dirt from sticking to the oil.