Purpose

To measure the condition of the power cylinders

Tools

• Magnehelic gauge on gauge bar or water manometer

• Crankcase pressure test adapter

Procedure

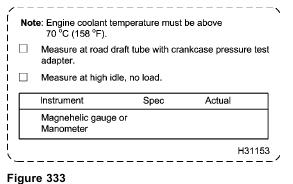

1. See “DT 466 Performance Specifications” – Appendix A (page 595) or “DT 570 and HT 570

Performance Specifications” – Appendix B (page 619) for specifications and record on Diagnostic Form.

2. Park vehicle on level ground.

3. Make sure the engine oil level is not above operating range and the oil level gauge is secured.

4. Make sure breather tube is clean, secure in valve cover, and the valve cover is tight.

5. Make sure all hoses are secure and not leaking.

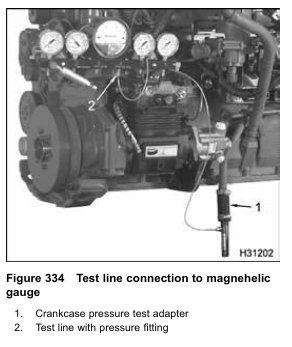

6. Install crankcase pressure test adapter to road draft tube.

NOTE: If the engine has a breather extension tube, the extension tube must be removed before testing.

7. Connect test line from the crankcase pressure test adapter to the magnehelic gauge on the gauge bar or to a water manometer.

8. Run engine to reach normal engine operating 70 °C (158 °F) or higher, before measuring crankcase pressure.

9. Run engine at high idle (no load) rpm. Allow the gauge reading to stabilize before taking pressure reading.

10. Record crankcase pressure on Diagnostic Form.

• If pressure is below specification, continue Performance Diagnostics.

• If pressure is above specification, continue with step 10.

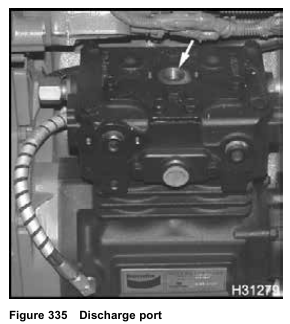

11. If engine has an air compressor, remove discharge air line and retest.

• If pressure is below specification, repair or replace air compressor.

• If pressure is above specification, continue with step 11.

12. Disconnect VGT control module and retest.

• If pressure is below specification, reconnect the VGT control module, and retest doing Test 13 (Air Management) to see if crankcase pressure increases as turbocharger demand increases.

If pressure fluctuates above and below specification, as the VGT is cycling, replace the turbocharger.

• If disconnecting or cycling the turbocharger does not bring pressure below specification, continue with step 12.

13. Do Test 12 Relative Compression Test to pin point suspect cylinders.

14. Do Test 11 Injector Disable to further pin point suspect cylinders.

15. Inspect air induction for dirt ingestion.

Possible Causes

High oil consumption and excessive crankcase pressure may indicate the following:

• Dirt in air induction system

• Badly worn or broken rings

• Cylinder sleeves badly worn or scored

• Leaking valve seals or worn valve guides

• A restricted orifice in crankcase pressure test adapter

• Failed turbocharger

• Failed air compressor

Low oil consumption and excessive crankcase pressure may indicate the following:

• Air compressor affecting crankcase pressure.

• A restricted orifice in crankcase pressure test adapter