NOTE: If Tests 1-17 meet specifications, engine operation is good: Test 18 is not necessary.

Purpose

• To check or adjust valve lash for intake and exhaust valves

• To check or adjust actuator lash for Diamond Logic® engine brake

Tools

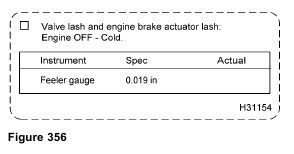

• Feeler gauge

• Straight-blade screwdriver

• Open end wrench (two sizes)

• Torque wrench

• Crows foot (two sizes)

Valve Lash for Intake and Exhaust Valves

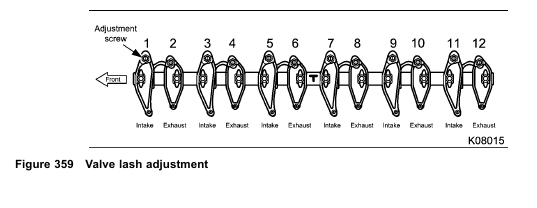

During the procedure to adjust valve lash, the crankshaft is rotated two times:

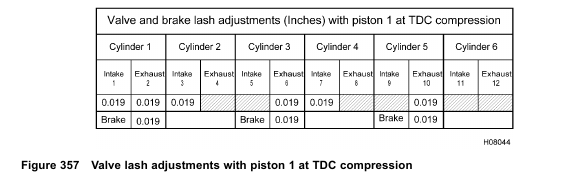

• Six valve adjustments are made when piston 1 is at Top Dead Center (TDC) compression.

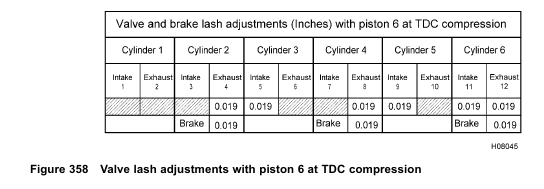

• Six valve adjustments are made when piston 6 is at Top Dead Center (TDC) compression.

If the engine is equipped with the Diamond Logic® engine brake, corresponding brake actuator lash can be adjusted before rotating the crankshaft the second time.

Adjusting Valve Lash

1. Remove valve cover following procedure in Engine Service Manual.

2. Turn crankshaft in the direction of engine rotation to remove gear lash from gear train and align the timing mark on the damper pulley with the TDC mark on the front cover.

3. Confirm that piston 1 is at TDC compression by turning both push rods by hand to verify that valves are closed.

• If push rods are loose and turn easily, piston 1 is at TDC compression and valves are closed.

If piston 1 is at TDC compression, see and do steps 4, 5, and 6.

• If push rods will not turn easily for cylinder 1, piston 6 is at TDC compression. Confirm that valves are closed by making sure that push rods for cylinder 6 are loose and turn easily. If piston 6 is at TDC compression, see and do

steps 4, 5, and 6.

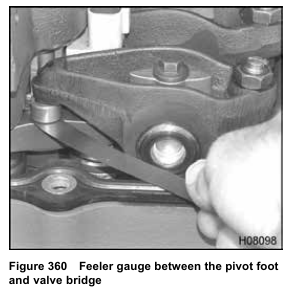

4. Check cold valve lash with a (0.019 in) feeler gauge between the pivot foot and valve bridge.

If adjustment is required, loosen the locknut and turn the valve adjustment screw until a light drag is felt.

5. Once valve adjustment is set, tighten the locknut to 27 N·m (20 lbf·ft) and remove the feeler gauge.

Recheck for light drag on feeler gauge. If drag is too tight or loose, repeat steps 4 and 5.

If engine is equipped with the Diamond Logic® engine brake, corresponding brake actuator lash can be adjusted before rotating the crankshaft. See “Brake Actuator Lash” in this section.

6. Turn crankshaft 360° in the direction of engine rotation to remove gear lash from gear train and realign the timing mark on the damper pulley with the TDC mark on the front cover.

• If first adjustments were with piston 1 at TDC compression, cylinder 6 should be at TDC compression. Confirm that valves are closed by making sure that push rods for cylinder 6 are loose and turn easily. If piston 6 is at TDC compression, see and do steps 4 and 5.

• If first adjustments were with piston 6 at TDC compression, cylinder 1 should be at TDC compression. Confirm that valves are closed by making sure that push rods for cylinder 1 are loose and turn easily. If piston 1 is at TDC compression, see and do steps 4 and 5.

Before doing step 7, If engine is equipped with the Diamond Logic® engine brake corresponding brake actuator lash can be adjusted. See “Brake Actuator Lash” in this section.

7. Install valve cover following procedure in Engine Service Manual.

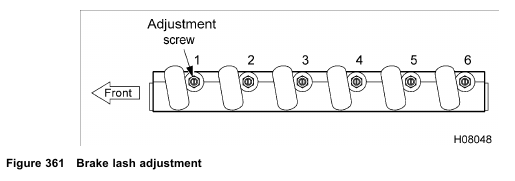

Brake Lash

• Three actuators are adjusted when piston 1 is at Top Dead Center (TDC) compression.

• Three actuators are adjusted when piston 6 is at Top Dead Center (TDC) compression.

Corresponding intake and exhaust valve lash should be adjusted before rotating the crankshaft.

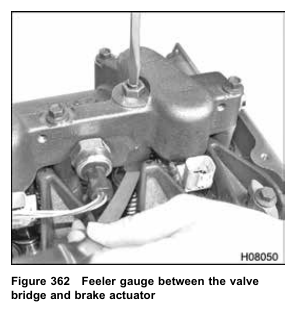

1. Check cold brake lash with a (0.019 in) feeler gauge between the actuator and valve bridge. If adjustment is required, loosen the locknut and turn the actuator adjustment screw until a light drag is felt.

2. Once brake lash is set, tighten the locknut to 27 N·m (20 lbf·ft) and remove the feeler gauge.

Recheck for light drag on feeler gauge. If drag is too tight or loose, repeat steps 1 and 2.

Possible Causes

• Worn valve train

• Worn valve seat or valve face

• Worn actuator in Diamond Logic® engine brake